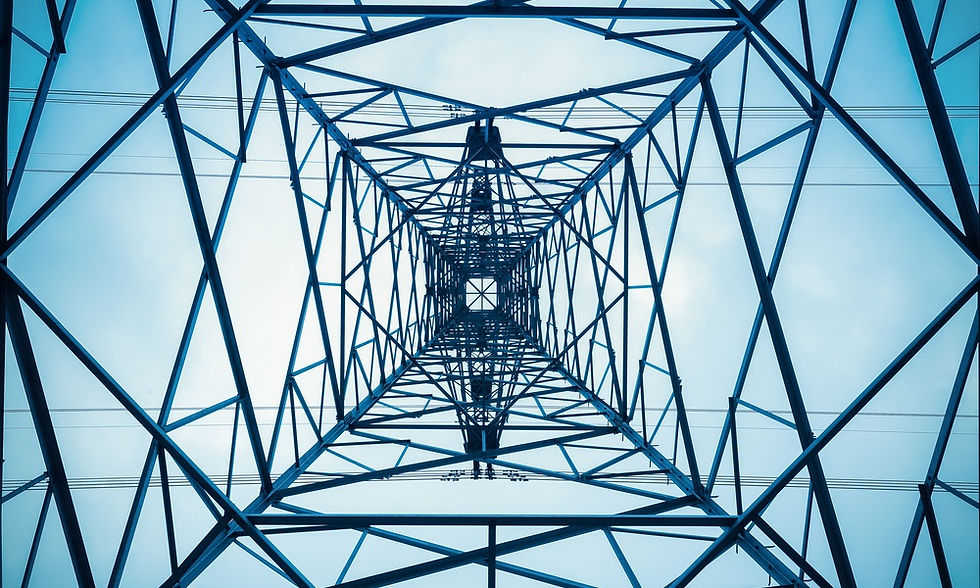

Best Practices for Monitoring Steel Tower Integrity

- The Chronicle News

- Dec 16, 2025

- 2 min read

Steel towers support everything from telecommunications to power transmission. Every tower faces persistent challenges from weather exposure to continuous operational demands. For those overseeing maintenance, these challenges call for a thoughtful approach that addresses potential risks early on. Adopting best practices for monitoring steel tower integrity lays a strong foundation for reducing hazards and extending the lifespan of these important structures.

Establish a Regular Inspection Schedule

Without consistent inspection routines, tower maintenance quickly loses its effectiveness. The frequency of these checks can depend on several factors, including the tower's age, location, and exposure to harsh weather. Creating a schedule and sticking to it allows teams to track the tower's condition over time and spot gradual changes that might otherwise go unnoticed.

Pay Attention to Material Fatigue

Over time, the constant stress from wind and other environmental loads can take a toll on the structure. Understanding the common signs of fatigue in steel tower members is essential for any maintenance professional. Small cracks or deformities can indicate that the material is weakening and requires immediate attention to prevent more significant structural failures.

Implement Advanced Monitoring Techniques

Beyond visual checks, modern technology offers more detailed ways to assess a tower's health. Nondestructive testing (NDT) methods, such as ultrasonic testing or magnetic particle inspection, can detect flaws that are not visible to the naked eye. Additionally, using sensors to monitor vibrations and strain can provide real-time data on how the tower is responding to environmental forces.

Foster a Culture of Training and Collaboration

Effective steel tower maintenance goes beyond tools and schedules. It also relies on a skilled, informed team. Consistent training keeps technicians up to date on the latest inspection methods and safety procedures. Workshops and certification programs can introduce new technologies and reinforce best practices. Moreover, encouraging open communication between teams means insights and findings from one project can lead to improvements in others.

Integrate Documentation and Historical Tracking

Maintaining thorough records of every maintenance activity can transform how teams approach steel tower care. Documenting each step creates a valuable history that helps identify recurring issues, schedule future work more effectively, and support compliance with industry standards. Organized documentation aids internal processes but also provides a reliable reference during audits or when bringing new team members up to speed.

Reliable strategies begin with knowledge and attention to detail. When you prioritize best practices for monitoring steel tower integrity, every inspection, upgrade, and decision becomes clearer. The effort you invest today supports not just the structure, but the people and operations that rely on it.

Comments